Likarolo tsa Moemeli

-

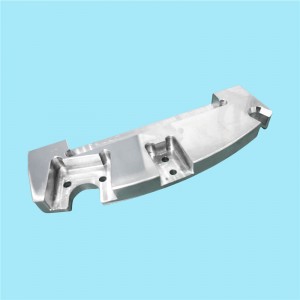

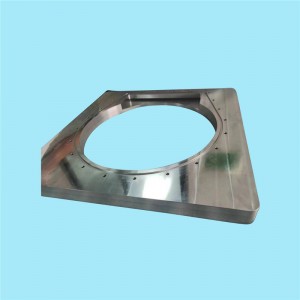

CNC Machining Hlakileng Anodised Aluminium Parts

Mefuta ea Mechini ea Aluminium!

Aluminium ea indasteri ea tlhahiso ha e khone ho sebetsana ka katleho ntle le aluminium.Ka tlase ke mefuta e 'maloa ea machining e nang le lebelo le phahameng le sebelisoang indastering.

1. Mechine ea Aluminium Prototype

Li-prototype tsa aluminium tse entsoeng ka mochini haholo ke lihlahisoa tsa mefuta e fapaneng ea li-alloys.Alloy e sebelisoang hangata ke 6061-T6, e koahelang lipalangoang, sefofane, lisebelisoa tsa elektroniki le liindasteri tsa sesole.

Li-alloys tsa aluminium li na le matla a phahameng le matla a tlase.Boholo ba nako, machining a Aluminium CNC a na le mamello e phahameng ea ho laola hoo e ka bang 0.01MM.Lisebelisoa tsa boleng le tse ikhethang tsa aluminium li ka etsoa ka CNC.Khetho e phethahetseng bakeng sa ts'ebetso ena ke CNC Milling, 'me e na le ho nepahala ho phahameng le ho nepahala ha ho sila aluminium.

Ho etsa prototype ka aluminium ho nka lits'ebetso tse 'maloa ho tsoa ho li-block tsa aluminium.Mefuta e mengata ea thekenoloji le metjhini e hlahisa moralo o motle ka ho fetisisa oa sesebelisoa se seng le se seng se entsoeng.

Baqapi le bahlahisi ba tloaetse ho qala lihlahisoa tsa bona Ka nako e khuts'oane ea ho boloka litšenyehelo.Mohlala o haufi le oa pele o tla etsoa.

-

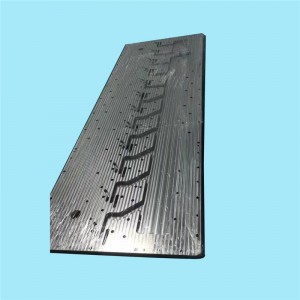

SUS304 CNC Ho sebetsa likarolo tsa tšepe tse sa hloekang

Mochini oa ho itšeha oa tšepe oa CNC ke eng?

Mekhoa ea ho itšeha ea tšepe ea ho laola lipalo ea k'homphieutha haholo-holo e kenyelletsa laser, lelakabe, plasma, joalo-joalo.Har'a tsona, mechine ea ho itšeha ea fiber laser le plasma ke eona e tsebahalang haholo.Ho ea ka lenaneo le ntlafetseng la ho itšeha le fanoeng ke software ea CNC nesting, ho ka khoneha ho itšeha ka mokhoa o itekanetseng, o sebetsang hantle le oa boleng bo phahameng.CNC ho itšeha tšepe ho emela mekhoa ea morao-rao ea theknoloji e phahameng ea tlhahiso.Lisebelisoa tsa mochini oa CNC oa tšepe ke sehlahisoa sa motsoako oa theknoloji e tsoetseng pele ea ho laola linomoro tsa k'homphieutha le mechine ea ho itšeha.Ha ho bapisoa le mokhoa o tloaelehileng oa ho itšeha ka letsoho, lisebelisoa tsa mochini oa CNC oa ho itšeha ka mokhoa o atlehileng o laola le ho ntlafatsa boleng ba ho itšeha le ho sebetsa hantle.

-

CNC Precision Machining Programming le Tsebo

Lenaneo la CNC (Computer Numerical Control Programming) le sebelisoa ke bahlahisi ho etsa khoutu e tsamaisang mosebetsi oa mochine oa CNC.CNC e sebelisa mokhoa oa tlhahiso ea subtractive ho khaola likarolo tsa thepa ea motheo ho theha sebopeho se lakatsehang.

Mechini ea CNC hangata e sebelisa likhoutu tsa G le likhoutu tsa M ho laola tšebetso ea machining.Likhoutu tsa G li laola boemo ba karolo kapa lisebelisoa.Likhoutu tsena li lokisa karolo bakeng sa mokhoa oa ho seha kapa oa ho sila.Li-M-code li bulela ho potoloha ha lisebelisoa le mesebetsi e meng e fapaneng.Bakeng sa lintlha tse joalo ka lebelo, nomoro ea sesebelisoa, cutter diameter offset le feed, sistimi e sebelisa likhoutu tse ling tsa alphanumeric ho qala ka S, T, D le F, ka ho latellana.

Ho na le mefuta e meraro ea mantlha ea mananeo a CNC - ka letsoho, tlhahiso ea lisebelisoa tsa khomphutha (CAM) le puisano.E 'ngoe le e' ngoe e na le melemo le likotsi tse ikhethang.Baqapi ba CNC ba qalang ba lokela ho ithuta hore na ke eng e khethollang mofuta o mong le o mong oa lenaneo ho tse ling le hore na ke hobane'ng ha mekhoa e meraro e le ea bohlokoa ho tseba.

-

CNC Machining SUS304 Likarolo tse hanyetsanang le Corrosion Haholo

Li-alloys tse hanyetsanang le Corrosion ke litšepe tse etselitsoeng ho hanela ho senyeha ka oxidation kapa liphetoho tse ling tsa lik'hemik'hale.Li-cra's tse atileng haholo, tse sebelisetsoang ho thibela kutu ho isa ho tse mahareng, ke litšepe tse se nang tšepe.Litšepe tse sa hloekang ke li-alloys tse thehiloeng ka tšepe tse nang le bonyane ba 10.5% chromium, e lekaneng ho thibela mafome tlas'a maemo a tloaelehileng a mocheso oa kamoreng.Litšepe tse se nang tšepe tse kopantsoeng feela le Chromium, joalo ka Mofuta oa 430, li bitsoa Ferritic Stainless Steels.Lelapa lena la li-alloys le ke ke la matlafatsoa ke phekolo ea mocheso, leha ho le joalo, ka ho eketsoa ha carbon le likarolo tse ling, li fetoha Martensitic Stainless Steels.

Mefuta e tloaelehileng ka ho fetisisa ea Martensitic Stainless Steels, Mefuta ea 410 kapa 13 Chrome, e matlafatsoa ke ho tima le mocheso oa mocheso.Ho boetse ho na le lelapa la Precipitation Hardened Martensitic Stainless Steels le kenyelletsang Mofuta oa 17-4 o sebelisoang haholo.Martensitic Stainless Steels e kanna ea ba le litlatsetso tsa Nickel le Molybdenum bakeng sa ho hanyetsa kutu.

-

Likarolo tsa tšepe tse sa hloekang tsa CNC tse Tloaelehileng

Mochini oa ho itšeha oa tšepe oa CNC o na le mefuta e mekae?

Mochini oa router oa CNC ke eng?

Ho na le mefuta e mengata ea mechine ea ho itšeha ea tšepe ea CNC.Har'a tsona, lisebelisoa tse ling tsa mochini oa tšepe oa CNC li ka khaola le ho betla lisebelisoa tse seng tsa tšepe, hape li ka sebetsana le lisebelisoa tse ling tsa tšepe (haholo-holo litšepe tse bonolo).Aluminium e na le botsoalle ba tikoloho ebile e ntle ebile e sebelisoa haholo liindastering tse ngata.Ka hona, o hloka mochine o motle oa tšepe oa CNC ho khaola aluminium.Mohlala, li-routers tsa ATC CNC, litsi tsa machining tsa li-axis tse hlano tsa CNC, mechini ea ho sila ea CNC, le lisebelisoa tse ling tsa mochini oa tšepe oa CNC li ka khaola lisebelisoa tsa tšepe tse bonolo.

-

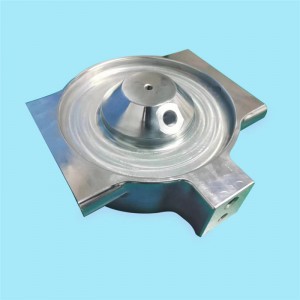

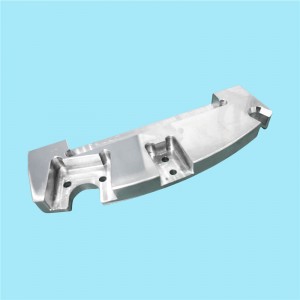

Custom Anodizing Aluminium CNC Milling Parts

Numerical control machining (CNC) e bua ka basebetsi ba mochini ba sebelisang lisebelisoa tsa ho laola lipalo ho tsoela pele ho sebetsa, lisebelisoa tsena tsa taolo ea linomoro li kenyelletsa setsi sa machining, setsi sa ho cheka, lisebelisoa tsa ho itšeha wedM, mochini o sehang likhoele joalo-joalo.Boholo ba lithupelo tsa ho lokisa mochini li sebelisa theknoloji ea ho sebetsana le lipalo.Ka ho etsa lenaneo, mosebetsi oa "workpiece" oa Cartesian coordinate boemo ba tsamaiso (X, Y, Z) ka puo ea lenaneo, CNC mochine oa CNC controller ka ho tsebahatsa le tlhaloso ea puo ea lenaneo ho laola axis ea mochine oa CNC, tlosa ka bohona. thepa ho ea ka litlhoko, e le ho fumana workpiece ea ho qetela.CNC machining e sebetsana le workpiece ka tsela e tsoelang pele, e loketseng likarolo tse ngata tsa sebopeho se rarahaneng.

-

Likarolo tsa tšepe tse sa hloekang tse entsoeng ka Black Oxide

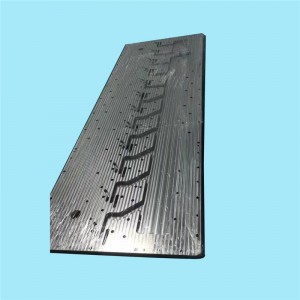

Mefuta ea Mechini ea Mechini

Mekhoa e 'meli ea mantlha ea machining e fetoha le ho sila - e hlalositsoe ka tlase.Ka linako tse ling lits'ebetso tse ling li tsamaisana le lits'ebetso tsena kapa li etsoa ka lisebelisoa tse ikemetseng.Mohlala, mochini oa ho phunya o ka kengoa leboneng le sebelisetsoang ho phethoha kapa ho kengoa mochining oa ho phunya.Ka nako e 'ngoe, ho ne ho ka 'na ha e-ba le phapang pakeng tsa ho reteleha, moo karolo e potolohang teng le ho siloa, moo sesebelisoa se potolohang.Sena se fositse ka mokhoa o itseng ha ho fihla litsi tsa machining le litsi tsa phetolo tse khonang ho etsa ts'ebetso eohle ea mochini o le mong mochining o le mong.

-

Alloy e thehiloeng ho Nickel e sebelisitsoeng ka Passivation

Mabapi le Li-Alloys tse thehiloeng ho Nickel

Li-alloys tse thehiloeng ho nickel li boetse li bitsoa li-superalloys tse thehiloeng ho ni-based ka lebaka la matla a tsona a ikhethang, ho hanyetsa mocheso le ho hanyetsa ho bola.Sebopeho sa kristale se shebaneng le sefahleho ke tšobotsi e ikhethang ea li-alloys tse thehiloeng ho nickel kaha nickel e sebetsa e le stabilizer bakeng sa austenite.

Likarolo tse tloaelehileng tsa lik'hemik'hale ho li-alloys tse thehiloeng ho nickel ke chromium, cobalt, molybdenum, tšepe le tungsten.

-

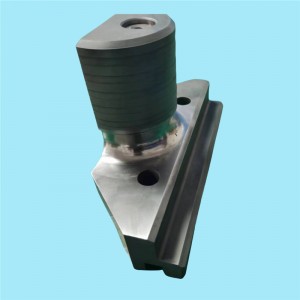

Electropolishing Stainless Steel CNC Machining

Kenyelletso ea Sehlahisoa

Likarolo tsa OEM CNC Machining ke likarolo tse entsoeng ka theknoloji e tsoetseng pele 'me hangata li entsoe ka tšepe ea boleng bo holimo.Hangata sefahleho se tšoaroa ka electroplating, penta, anodizing, electropolishing, coating, joalo-joalo, kahoo e ntle haholo ebile e boreleli, ntle le li-burrs.Re na le lilemo tse ngata tsa boiphihlelo ba tlhahiso ho netefatsa hore likarolo tsohle tsa rona tsa OEM CNC Machining ke tsa boleng bo holimo ebile li nepahetse.Haeba ho na le tlhoko, re ka u etsetsa eona.

-

Likarolo tsa Machining tsa Stainless Steel Precision CNC

PRECISION MACHING KE ENG?

Precision machining ke mofuta oa tlhahiso ea tekheniki o bohlokoa ho theheng le ho rala metjhini, likarolo, lisebelisoa le lisebelisoa tse ling tse bohlokoa tlhahisong ea sejoale-joale ho boloka taolo ea ts'ebetso le mamello e sebetsang tlasa maemo a thata haholo.E sebelisoa ho etsa lintho tse ngata tse kholo le tse nyane le likarolo tsa tsona tseo re li sebelisang bophelong ba letsatsi le letsatsi.Haeba ntho e entsoe ka likaroloana tse ngata tse nyenyane, hangata li tla hloka ho etsoa ka machining a nepahetseng ho etsa bonnete ba hore li kopana hantle le ho sebetsa hantle.Precision Machining e ka hlalosoa e le ho sebelisa ts'ebetso e phahameng ka ho fetesisa ea sesebelisoa, lenaneo, talenta ea boenjiniere kapa lisebelisoa, ka hona ho sutumelletsa meeli ea sebopeho sa sebopeho sa sebopeho le mahlale a thepa le ho etsa ts'ebetso ena tlasa mamello e matla ka ho fetesisa e hlalosoang ke karolo efe kapa efe ea likarolo tsena tsa tlhahiso.

-

Likarolo tse nepahetseng tse hlahisitsoeng ke CNC Machining

KE LISEBETSI FE LE LITSEBE TSE SEBELISANG BAKENG SA PRECISION MACHING?

Ho sebetsa ka mokhoa o nepahetseng ho ka sebelisoa ka lisebelisoa tse ngata tse qalang tse kenyelletsang (empa ha li felle feela) polasetiki, ceramic, tšepe, metsoako, tšepe, boronse, graphite le khalase.E le ho etsa maqeba a nepahetseng le ho tlosoa ka mokhoa o rarahaneng oa thepa e tala, ho ka sebelisoa motsoako oa lisebelisoa.Lisebelisoa tsena lia fapana ho latela thepa e tala.Lisebelisoa tse sebelisoang khafetsa li kenyelletsa mechini e silang, lilathe, Mochini o fehlang Motlakase (aka. EDM's), lisakha le lisila.Lisebelisoa tse sebelisoang hangata ke mochini o boima o laoloang ke komporo o etselitsoeng le ho sebelisoa ho tlosa thepa ea substrate e etsang likarolo tse qaqileng le likaroloana.Maemong a mang, esita le liroboto tse potlakileng le lits'ebetso tsa photochemical li ka sebelisoa ho fihlela sephetho se lakatsehang bakeng sa sehlahisoa sa ho qetela.

-

Mefuta ea Likarolo tsa Stainless Precision CNC

Litšebeletso tsa Machining tsa Stainless Steel CNC

Ho feto-fetoha ha tšepe ea tšepe e sa hloekang ha ho pelaelo.E sebelisoa liindastering tse fapaneng tsa machining tsa CNC (Computer Numerical Control).Lintho tse ngata tsa tšepe tse sa hloekang li hlahisoa ka mekhoa e fapaneng ea ho etsa mochini oa CNC.Mekhoa ena e rua molemo ka ho nepahala ha mechine e silang e laoloang ke k’homphieutha, liboro, lilathe le lisebelisoa tse ling tse sehang tse ka hlahisang likarolo tse nepahetseng, tse ka phetoang ka mokhoa o atlehileng le ka mokhoa o baballang chelete.